Replica Food Manufacturing Process

Here we will introduce the current process using plastic resin and silicone.

(Case Study Provided by Iwasaki Bei )

Consultation

Sales representatives ask restaurants for what they want, and propose optimal replica foods to the restaurant.

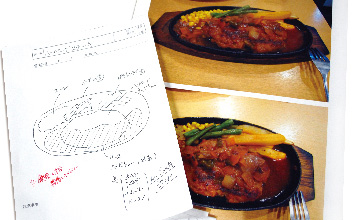

Making a Record of Food

The actual food is provided from the restaurant, and a detailed record is made with photos and sketches of the ingredients and cooking methods.

Examine Samples of Food

The ingredients of the samples of food (real food) brought back by the sales representatives are broken down, and are separated into those which require molding and those which can use off-the-shelf items.

Molding

Molds are taken of the ingredients that need molding by covering them with silicone. When the samples of food are removed from the hardened silicone the following day, the mold is complete.

Shaping

Plastic resin which has been colored with the food color is poured into the silicone mold and is then heated in an oven. The heat-cured plastic resin is removed from the mold to be used as parts.

Coloring

The parts are colored, using airbrushes and brushes.

Arranging

The colored parts are then arranged on a vessel. If necessary, there is secondary processing to add a sauce, or finishing work such as polishing etc.

Inspection

Prior to delivery, representatives carefully check to ensure that the product meets the customer’s demands.

Delivery

In most cases, the sales representatives will deliver the replica foods to the restaurant. At the same time, they will make suggestions as to how to most effectively display them.